Great Quality Wooden Pellets Pressed Natural Solid Fuel in Bulk From Manufacturer, 15 Kg Packs Wood Pellet

Product Description

FOB:160 dollars per ton

Material: 100% wood

Wood: pine, spruce, beech, oak, poplar, etc

Diameter: 8 mm

Shape: rod

Length: 8-30 mm

Calories: 4300-4900 Kcal/Kg

Water content: 10%

Ash content:<3%

Packaging bag one ton

Package according to the Buyer's specifications.

Wood pellets are a kind of fuel with high calorific value, which make the boiler run smoothly. They are friendly to the environment and not detrimental to users. Wood pellets are a source of waste for agriculture and other industries. We are manufacturers and supplies of Original Premium Wood Pellets with top quality & best specifications below:

1, low moisture and ash, non coking with sulfur free

2, 100% made of oak wood sawdust with high heating value & firepower

3, long burning time, high energy content

4, Minimum carbon dioxide, ensure fresh environment.

5, After burned, ash can be used as fertilizer, not harmful to the environment.

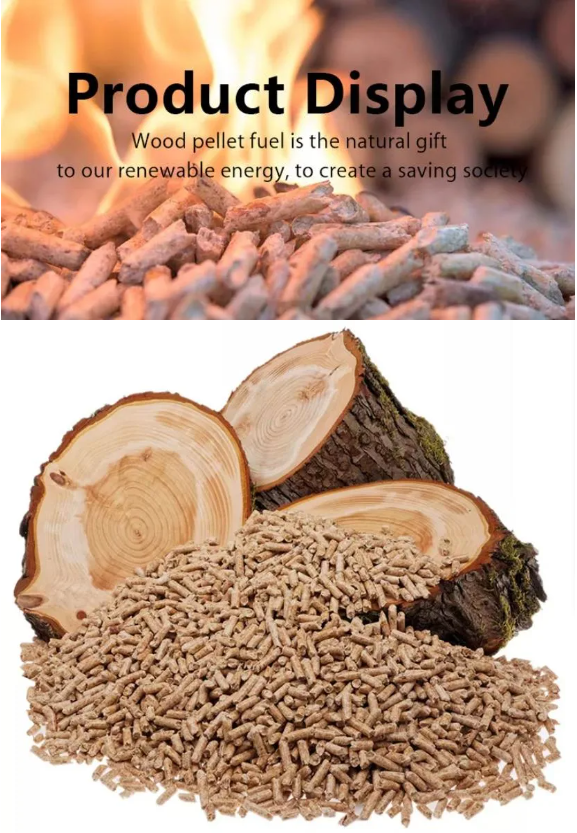

Wood pellets are a renewable resource, a fuel that is already widely available in the world nowadays. The sawdust or wood shavings are compressed under great pressure and forced through holes. This is a hot process and the natural lignin in the sawdust/wood shavings melts and binds the dust together, holding the pellet in shape and giving it that characteristic sheen on the outside.

Economic efficiency: Wood pellets are extremely dense and can be produced with a low moisture content (below 10%) that allows them to be burned with a very high combustion efficiency. Their high density also permits compact storage and rational transport over long distances. Electricity generated from pellets in converted coal plants is almost the same cost as electricity generated from natural gas, and diesel.

Environmentally friendly: Wood pellets are a sustainable fuel that can deliver a significant reduction in net carbon emissions when compared with fossil fuels. Its production and use also bring additional environmental and social benefits.

Using scopes: Biomass fuels replace fossil fuels in power plants, stoves, the boiler of textiles, food, leather, animal feeding, dye industries, and animal bedding.

Raw materials (sawdust, etc.) enter the crusher where it is crushed to flour. The received mass enters the dryer then to the pellet press, where the wood flour is compressed into pellets.

Mechanical Durability 98%